SMARTPIT: Feasibility analysis of the automation of your processes

Are you thinking about automating the processes of your production plant but you are not ready to take the step? Keep reading this post and we will help you to solve your doubts.

Automation is not an overnight decision, it depends on many factors and each plant or pit is completely different, from the shifts of the operators, arrival of trucks, cubic capacity of the grabs or buckets, crane speeds, pit size, whether the evacuation lines are belts or hoppers, etc. ....

What is SMARTPIT?

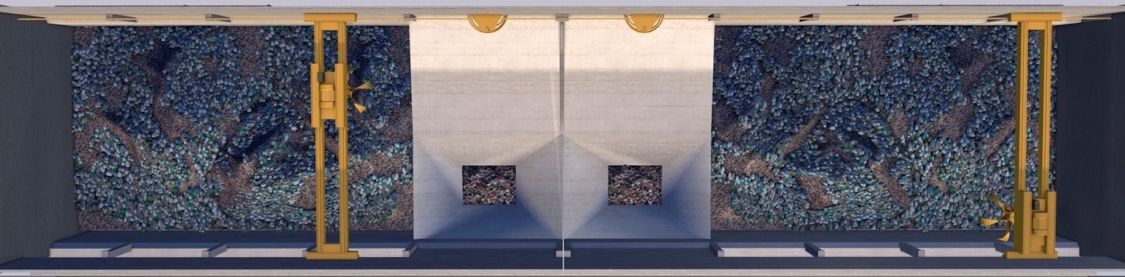

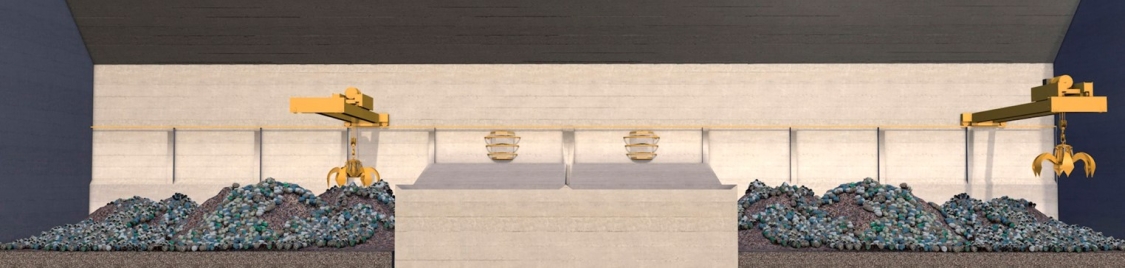

SMARTPIT is a technological solution offered by Vi4Crane to companies that manage materials in the pits of their facilities, in order to help in the digital transformation of the company, analysing the feasibility of automating their processes in these pits.

The SMARTPIT system provides essential data capture of key processes and monitoring of the data for further analysis using Business Intelligence (BI) and Artificial Intelligence (AI) tools.

The duration established for the capture and monitoring of this data is set at a period of approximately 15 days.

If your plant already has a weighing system, the value of the data obtained is greater as the final analysis will provide a more objective view of the feasibility of automating the material management processes in the pits.

What data is collected in SMARTPIT?

The main data collected by the SMARTPIT system are as follows:

- X-axis and Y-axis position data

It allows recording the positions and coordinates of the trajectories of the cranes and manipulators within the process in order to study the possible improvement actions to be carried out within the final automated solution.

-

Height of material in the pits

The height of the material in the pits makes it possible to control the average volume of material in daily operations, allowing access management to maximise the efficiency of the process by limiting interference with the handling and transfer elements.

-

Weight (tn) (if weighing system is available)

In the case of not having a weighing system, Vi4Crane can offer the possibility of incorporating it into its data capture devices as part of the equipment rental offer.

-

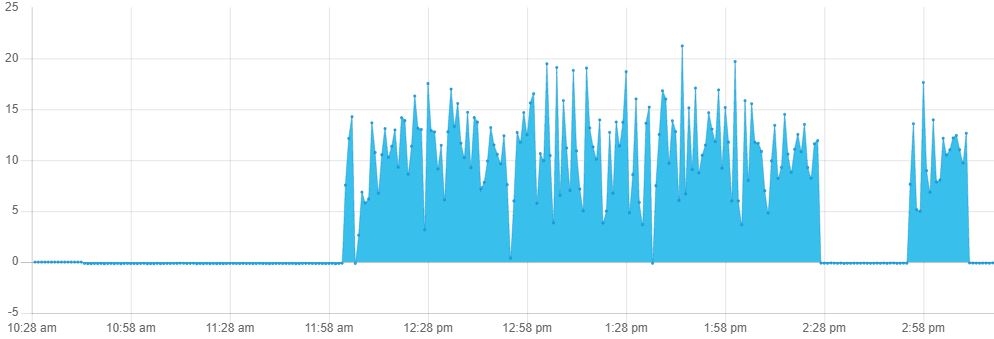

Electricity consumption in KW related to your process

The incorporation of measuring equipment in its translation and handling elements allows the control and analysis of the electrical consumption associated with the processes. This analysis makes it possible to dimension the management of the processes in such a way that the improvements of the Vi4Crane automation system serve to optimise the energy expenditure associated with the plant.

The data collected by SMARTPIT have an intermediate refresh rate between 1 or 2 seconds.

Likewise, the data collected will always remain the property of the client, as well as the report generated with the improvement actions and the established Roadmap. The confidentiality of this data is of vital importance to Vi4Crane within its Data Protection and Confidentiality Plan.

If you liked the article and want to know more about SMARTPIT, don´t miss the following article, "How does the customer get value from SMARTPIT".