Hardware

We have a solid, reliable and flexible basis in terms of different hardware options for different environments and functions.

GIITS System

The wireless GIITS (Grab Intelligent Interface and Transmission System) and its range GM-GE enables reliable, real-time communication between the grab and the crane´s PLC. It consists of a transmitter/receiver assembly to simplify wiring and improve the quality of operating information, opening the door to possible automation.

The main advantage of GIITS technology is that the automation of manipulators is made much simpler and cheaper. It even opens the door to the modernisation of equipment that does not have the necessary electrical wiring in the reel.

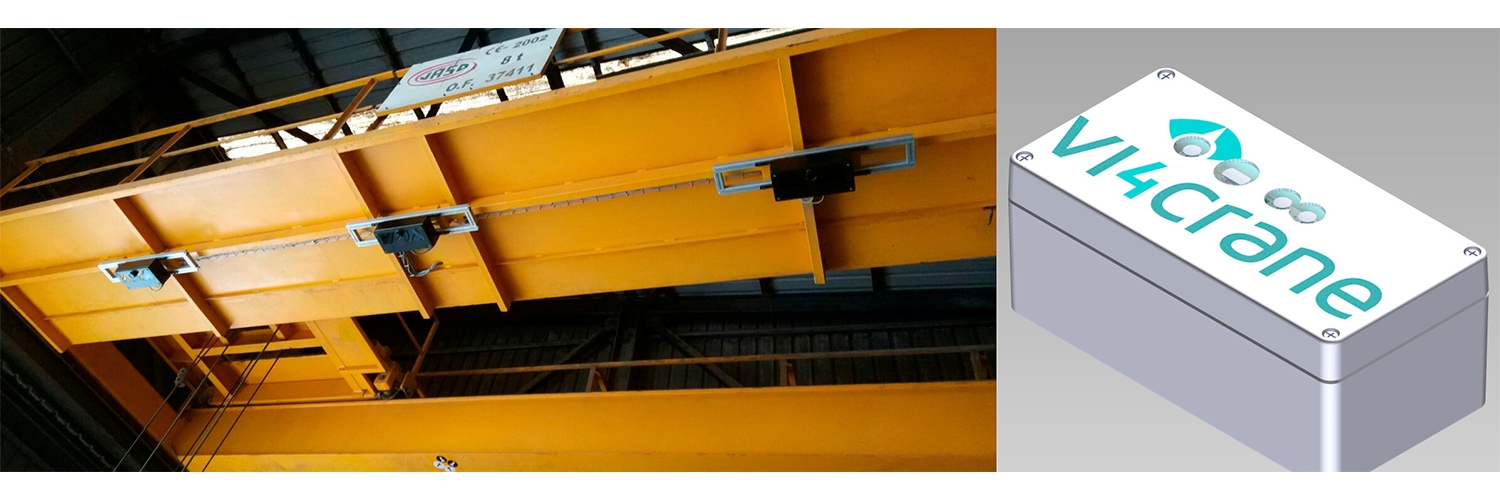

Main cabinet and field sensors

The Vi4Crane interconnection cabinet operates in parallel to the original crane systems, without disabling any of their safety features. This cabinet integrates a large part of the process electronics and is designed ad-hoc for quick integration into the plant. In this sense, we can use wireless technology for the emission and reception of signals or a wired connection. In any case, the electrical connections are designed with standard connectors to facilitate assembly, testing and maintenance.

The field sensors are a fundamental part of the installation, as they allow information to be collected from the different sub-processes. For this purpose, we have different technologies for detecting position, weight and invasion of trucks in plants that do not have their own hardware. In addition, we install specific cleaning tools to get the most out of these sensors.

Vision sensor

This is the heart and main element for the smart management of the pit. These vision sensors SV-400 can be either on-board the bridge crane or statically positioned in easily accessible areas of the pit. The quantity, position and type of sensor is defined in the commercial design phase of the installation, optimising its cost to meet the requirements of the project scope. The technology of our vision sensors enables high performance even in environments with high levels of dust, as even after several months of operation without being cleaned, they are able to map the material. As a proprietary product with a standard design concept for various purposes, we manage to minimise the number of component references for each project and the stock of spare parts.