Specialists in process control

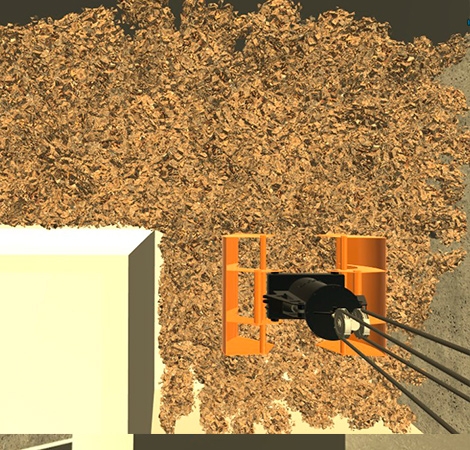

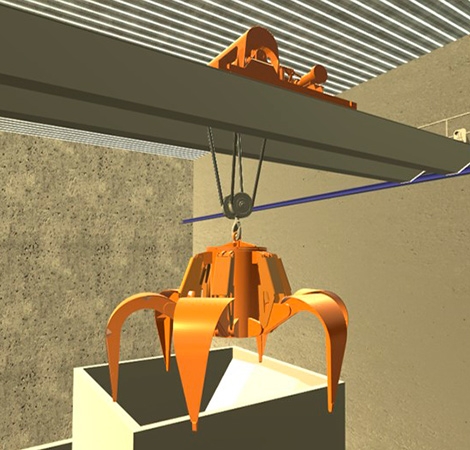

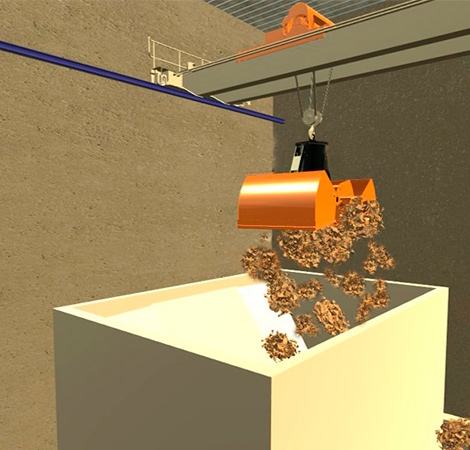

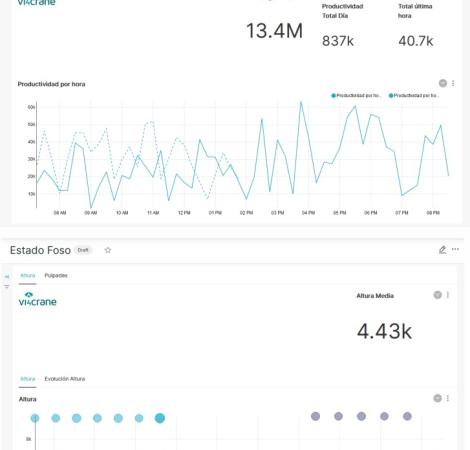

We provide our knowledge in the management of storage pits for different materials to efficiently control all their variables.

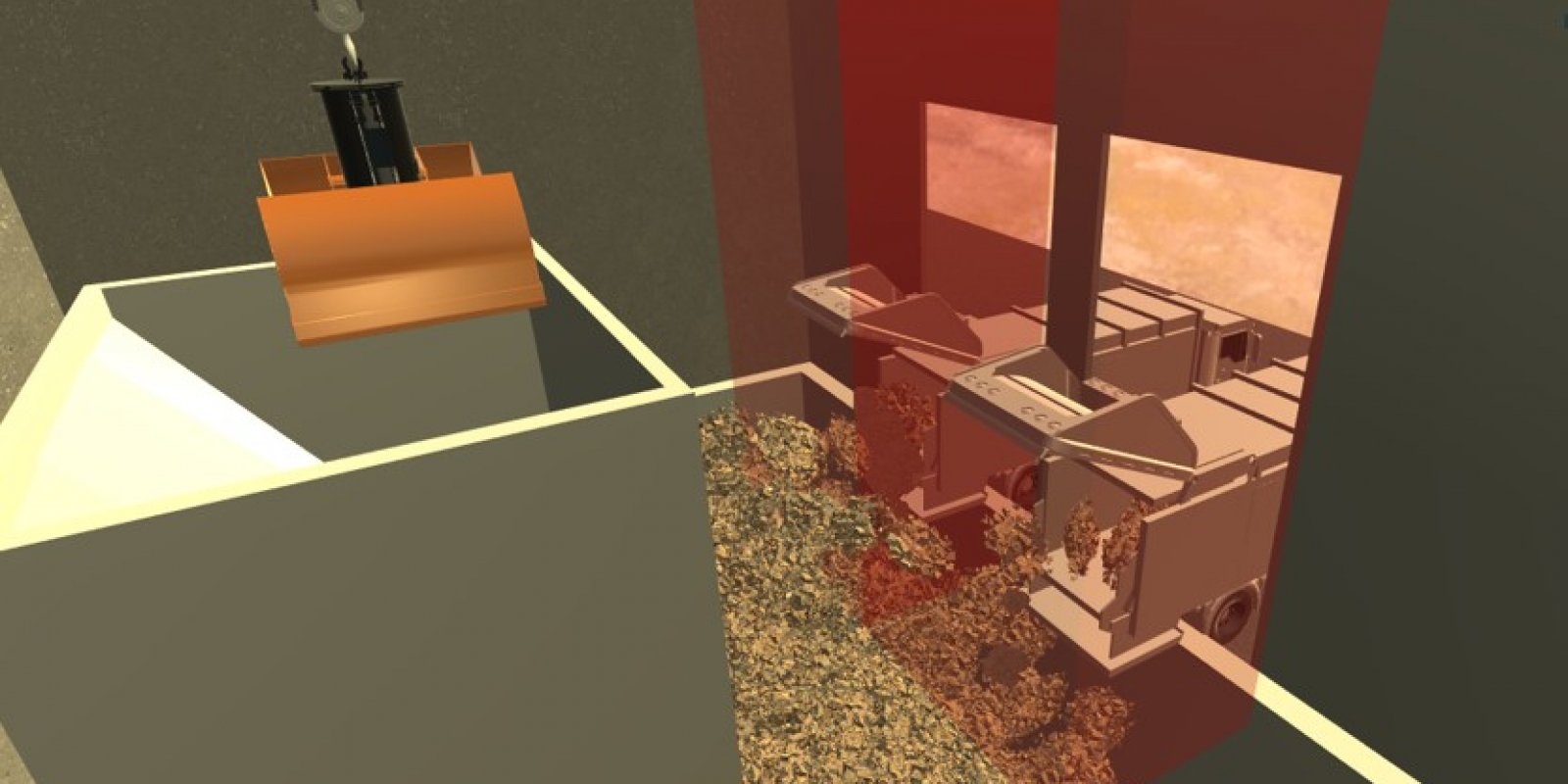

Integrated storage pit management

We identify the problem in each case and adapt the layers and functionalities of our product to optimise its cost.

Smart and scalable technology for every type of plant

We sensor the operational equipment available in the plant to monitor, automate or optimise parts of the process or its entire management.

About us

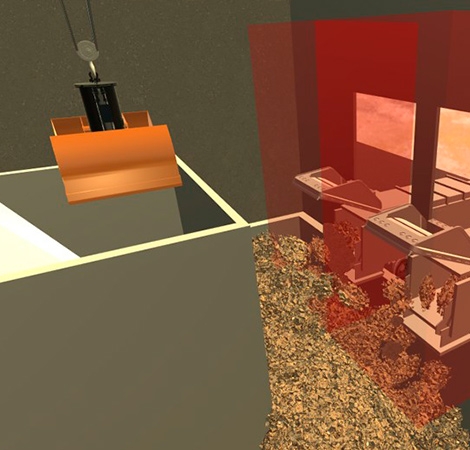

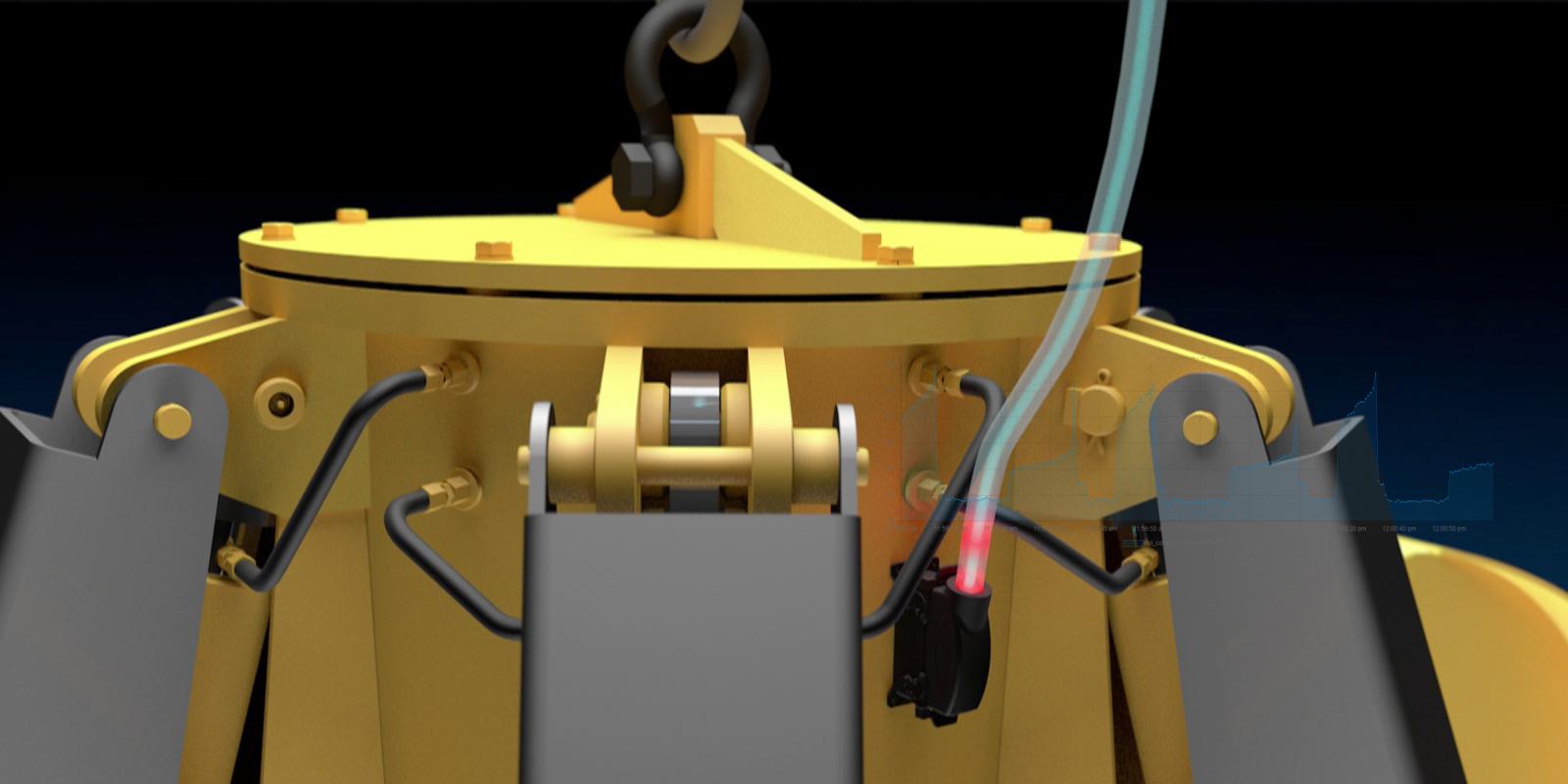

Vi4Crane is a technology-based company dedicated to providing solutions to bulk material handling processes using overhead cranes. As specialists in the automation and knowledge of processes related to the management of materials in pits, the technologies applied by Vi4Crane to improve these processes are automation, IoT, Industry 4.0 and Vision and Artificial Intelligence, among others. In resume, the company puts technology at the service of management to guarantee the productive regularity of processes that are sometimes poorly quantified, turning each pit into a controlled and optimised environment.

How can we help you?

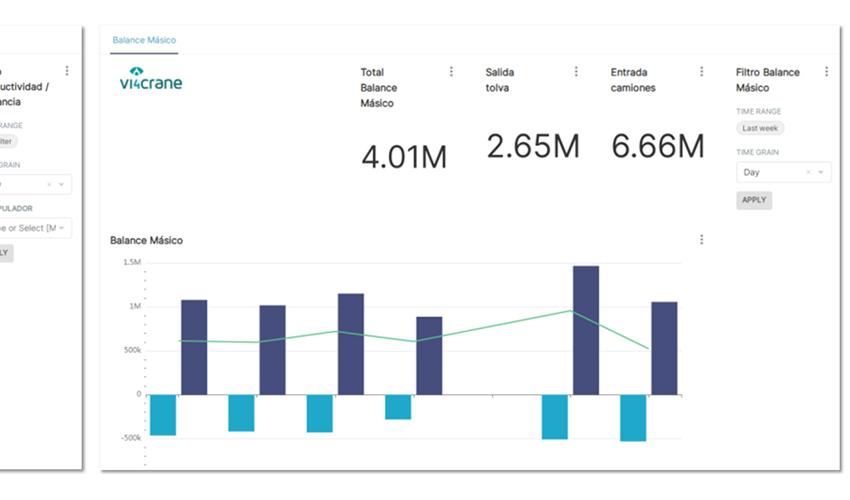

At Vi4Crane we care about generating an efficient behaviour in your production plant. If you are thinking about knowing the real time data of your production plant, you want to automate the processes ensuring a repetitiveness of the movements or you want to improve the decision making by optimizing your processes, we can help you.

Customised solutions

Find the solution that best suits your needs, whether it is a larger scale project where the degree of customisation is key to the final result of the project or, on the contrary, specific needs that you want to cover where pay-per-use takes on a very relevant role.

Product layers

Obtain information from each of the sub-processes of the material flow. These layers are used to modularise the solution on each case, adapting to different scenarios in terms of both complexity and scope.

Flexible and configurable

Flexible and configurable layout, work modes and priorities.

Ad hoc proposal

Development of ad hoc working methods adapted to the specific needs of the client.

Continuous improvement

Pit material monitoring by machine vision. Volume, image, classification on the basis of relevant characteristics.