Cranes and grabs

The technology responsible for monitoring and automating the cranes and grabs is made up of commercial automation elements, proprietary software and internal product-hardware development. The scope of the integration of this module varies, as it can be limited to monitoring the process or it can completely automate its operation.

With monitoring it is possible to obtain detailed information on the process, detect and store loads, unloads, movements, production data, etc. In short, it is a question of having quality data that allows the foundations to be laid for future improvement actions and to generate KPIs that provide added value for the operation of the plant.

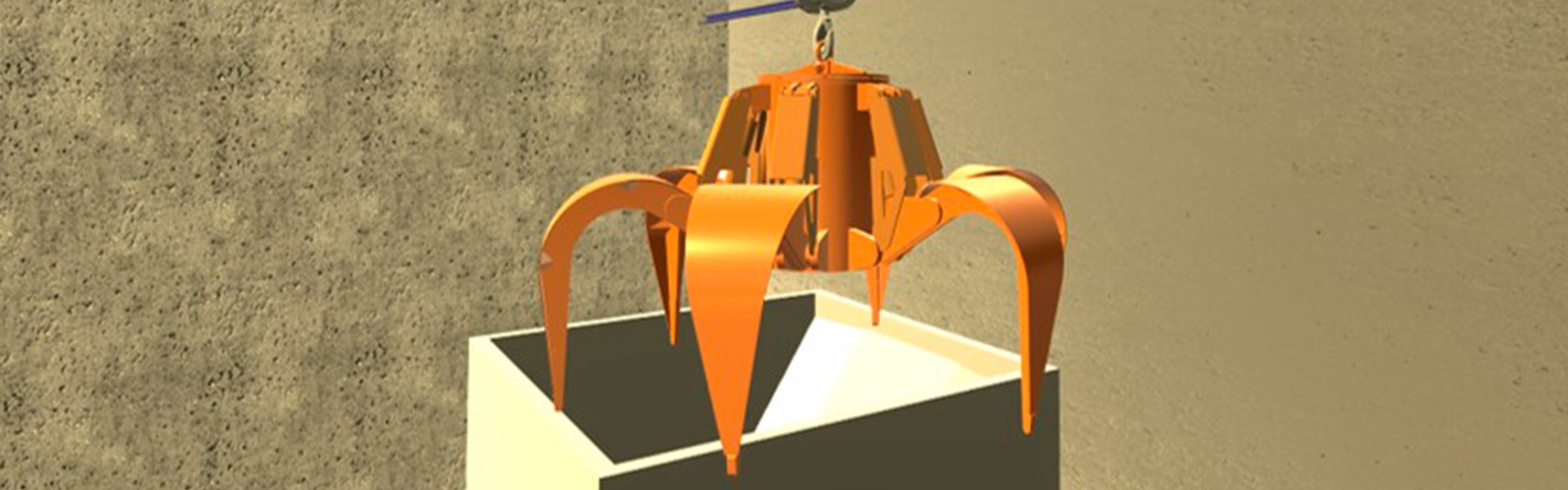

With the automation of the grabs, an optimisation of the manoeuvres adapted to the problems of the plant is achieved. With an easily configurable layout, different zones, materials, work modes, priorities, etc. can be defined. It is also possible to contemplate different work modes for different tasks to be carried out by the manipulators. The sensorisation of the manipulators is carried out by incorporating the GIITS system (Grab Intellegent Interface System) so that the information from the sensors is transmitted wirelessly. In this way, the level of control of the manipulators is improved without the need to increase the number of reel wires.